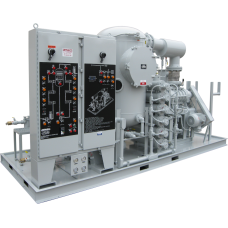

Hi-Vac Insulating Oil Purifiers (HHV Series)

As a result of rising cost of oils, increasing environmental regulations, liability and disposal cost, and new stringent vacuum requirements for manufactures warranties to .4 Torr @ 48hours, it is no longer economical to replace electrical insulating oils with new fluid. Instead, proper treatment of these fluids with our proven Hi-Vac Series renews dielectric strength and lowers residual water content by restoring oils to their original strength through vacuum dehydration & purification. Improvement of the entire insulating media of power transformers is obtainable with our HHV series High Vacuum (Hi-Vac) Oil Purifier. Our design meets the operational, economic, and environmental needs of industry and maintains the quality of insulating oils at the time of initial impregnation, filling at the factory, and maintains the same quality in field operation.

Our proven Hi-Vac provides reportable dehydration, degasification, and filtration techniques that remove even trace amounts of water to less than 5PPM and gases to less than 0.25%. An easy to read flow chart is provided on the electric panel and is superimposed over all switches, buttons, and indicating/warning lights. Our Hi-Vac can be used as stationary units or manufactured within a variety of trailer configurations to be completely portable or self contained.

Specifications

- Flow rates from 30 GPH to 3,000 GPH (higher capacities upon request)

- Vacuum pump capacity to 3,000 CFM (higher capacities upon request)

- Maximum vacuum pressure (blank off) to 0.01MM Hg (10 micron)

- Typical operating vacuum range during oil purification from 0.5 MM Hg to 5MM Hg

- Full range of heater capacities available including pre and post heaters

- Available in a variety of voltages to meet your specific operating requirements

- Pre & Post filtration from 150 to 1/2 micron

- Moisture Meters

Features & Performance

- Dehydration—At minimum oil temperatures of minimum 80°F water removal begins up from 100 PPM to less than 5PPM

- Degasification—Reduce soluble air content in a single pass from full saturation of approximately 12% to less than .25%. Other gases in solution with oil are also removed

- Pre-filter and polishing filter options with a full range of heater capacities

- Removes free & emulsified (total) water to less than 10 ppm, free & dissolved air & gases to 0.25% of total gas content. Varnishes, acids, resins, and oxidized agents using unique media

- Fullers earth, activated carbon, and activated alumina filter systems available for stripping acids and surfactants

- Fully pre-piped, pre-wired, factory tested and shipped for immediate installation

- Controls designed for manual or fully automatic operation

- Capable of full integration into monitoring & control systems using Programmable Logic Controller (PLC) options

- Electrical components enclosed in NEMA 4 weatherproof housing or NEMA 7 explosion proof housing

- Easy to read flow chart is on the electrical panel, over all switches, buttons, and indicating/warning lights

- Nitrogen Cold Trap Option

- Full flow hydraulic relief valves

Options

- Single button shut down

- Continuous Moisture-in-Oil Monitor

- Inhibitor injection system

- Compact Programmable Logic Controller (PLC)

- Variable speed driven

- Gallon meters

- Hose reels

- Built in containment

- Available in a wide range of options & skid configurations